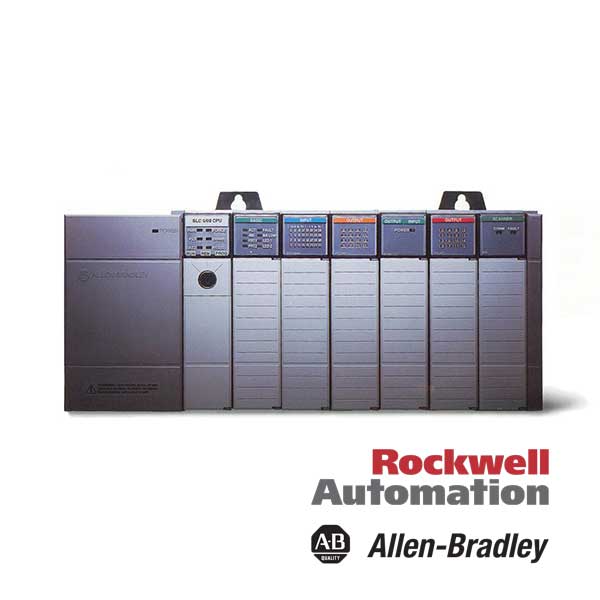

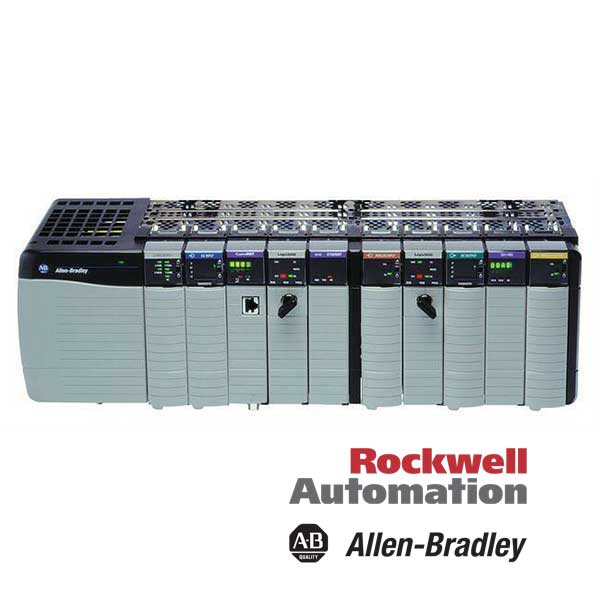

Allen‑Bradley PLC Systems

- Make: Allen Bradley (Rockwell Automation)

- Type: PLC5 / SLC500/ Micro Logix/ Compact Logix/ Control Logix

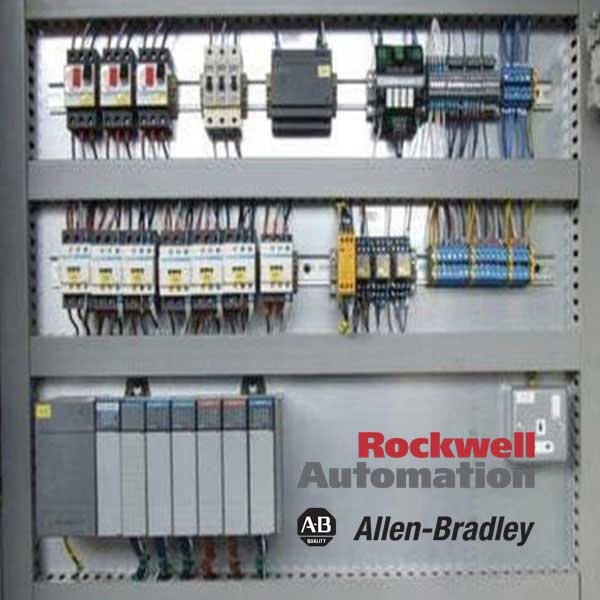

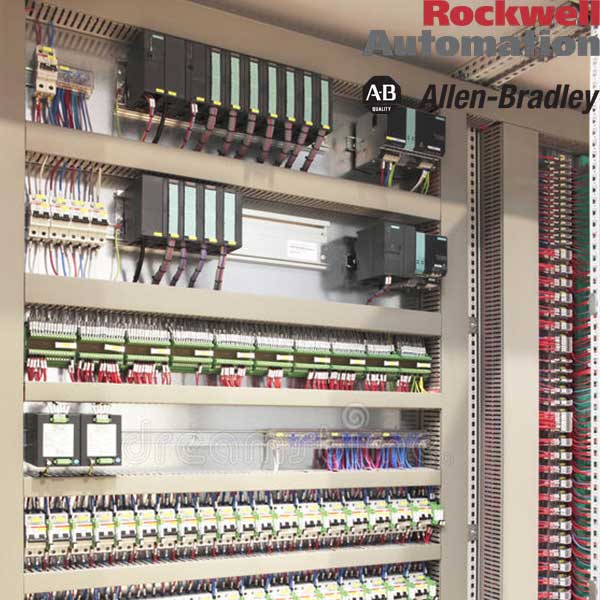

- System Intrigation: Drive System, Intrigation with Panel, HMI and SCADA.

- Project: Customizations, Modification and Trunky Project Working.

- Data Uses: Data Logging and Report Presentation

- Automation of Plant: Oil and Gas/ Process Plant/ Pharmaceuticals/ Injection Molding/ Packaging/ Manufacturing Plant/ Foods and Beverage

- Monitoring System: SCADA and HMI

- Controls: Automation Controls, Manual Controls, Test Controls and Quality Inspection.

Allen Bradley (Rockwell Automation) offers a wide range of Programmable Logic Controllers (PLCs) including the PLC5, SLC500, Micro Logix, Compact Logix, and Control Logix. These PLCs are designed to meet the demands of various automation applications in a variety of industries such as oil and gas, process plant, pharmaceuticals, injection molding, packaging, manufacturing plant, food and beverage.

The Allen Bradley PLCs offer exceptional performance and reliability in complex control systems. They are highly customizable and can be modified to meet specific project requirements. Additionally, the PLCs support trunky project working and can be integrated with other systems such as drive systems, panels, HMIs and SCADA.

One of the key features of the Allen Bradley PLCs is the data logging and report presentation capabilities. The PLCs can collect data and present it in an easily accessible and understandable format, providing valuable insights into the performance of the automation system.

The Allen Bradley PLCs are also capable of automation controls, manual controls, test controls and quality inspection, ensuring precise and accurate control of the plant operations. The monitoring system of the PLCs is designed to provide a seamless integration with SCADA and HMIs, allowing operators to monitor and control the automation system with ease.

The Allen Bradley PLCs are constructed using high-quality materials, ensuring durability and long-lasting performance even in harsh environments. They are designed to withstand extreme temperatures, humidity, and vibration, making them suitable for use in rugged industrial applications.

Additionally, the Allen Bradley PLCs are certified to meet various safety and performance standards, including UL, CE, and RoHS, ensuring compliance with global regulations and providing customers with the highest level of quality assurance.

Overall, the Allen Bradley PLCs are an attractive option for automation applications in a variety of industries. They offer exceptional performance, reliability, and customization options, making them suitable for both simple and complex automation projects. With their advanced data logging and report presentation capabilities, high-quality construction, and safety certifications, the Allen Bradley PLCs provide customers with a reliable and efficient solution for their automation needs.