In the vast world of industrial manufacturing, a transformative wave is sweeping through, and it goes by the name of Industry 4.0. This isn’t just some tech buzz; it’s a game-changer that’s reshaping how things are made. Let’s dive into the nuts and bolts of this revolution, breaking down complex ideas into bite-sized pieces.

“Industry 4.0 isn’t just a revolution; it’s a collaboration between human ingenuity and machine precision.”

Understanding Industry 4.0

Industry 4.0 is like giving a traditional factory a futuristic makeover. It’s the smart evolution of manufacturing, where machines talk to each other, and everything is connected. Think of it as a high-tech orchestra, where machines harmonize seamlessly to produce the perfect symphony of goods.

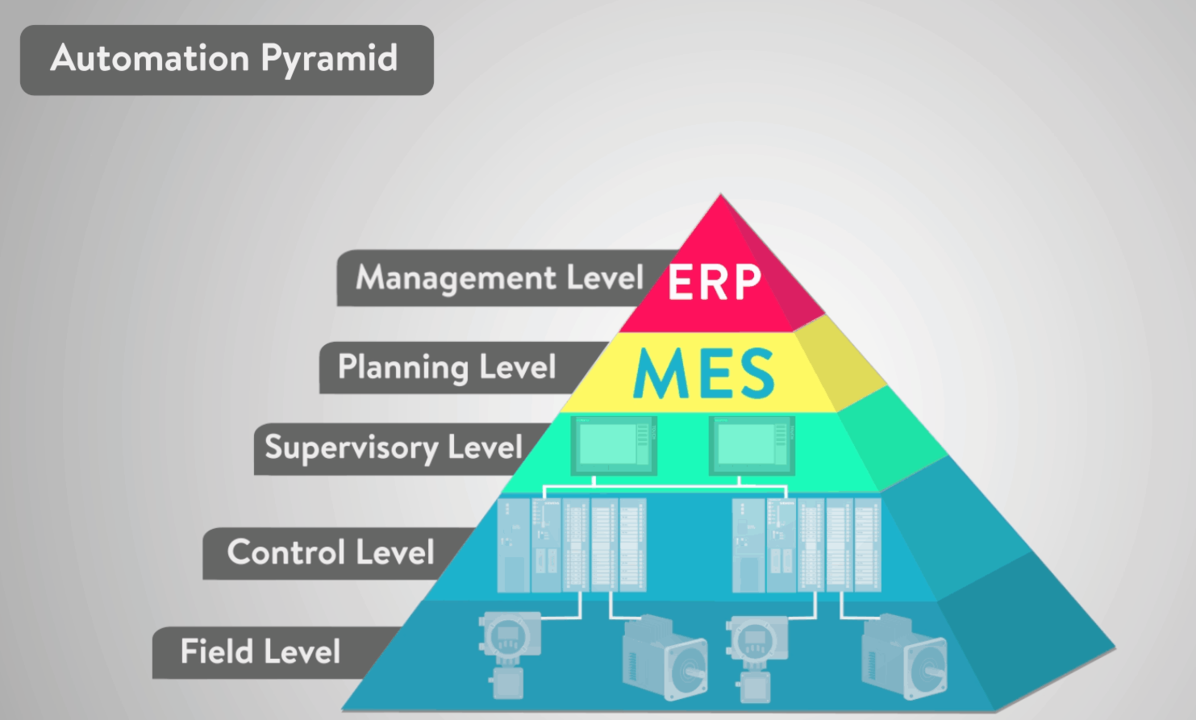

Smart Factories with Industry 4.0

The heart of Industry 4.0 lies in smart factories. These are not your typical assembly lines; they’re intelligent powerhouses. Machines equipped with sensors and processors communicate in real-time, making split-second decisions. It’s like having a production line with a built-in brain.

Internet of Things (IoT)

In simpler terms, IoT is the internet for everyday objects. In Industry 4.0, machines, products, and even tools are connected, sharing information effortlessly. It’s like your smartphone syncing with your smartwatch, but on a grand industrial scale.

How Does It Work?

Imagine a scenario: a product on the assembly line has a sensor that detects a tiny flaw. Without missing a beat, the machine communicates this flaw to other machines, triggering an immediate fix. It’s like having a team of superheroes with super-fast communication skills.

Big Data Analytics

One of the superheroes in this scenario is big data analytics. It’s not just about collecting data; it’s about understanding it. Machines analyze colossal amounts of information, helping businesses make informed decisions. It’s like having a crystal ball that predicts the future of production.

Artificial Intelligence (AI)

AI, the brainy sidekick, adds a touch of genius to Industry 4.0. Machines learn from experience, adapt, and optimize processes. It’s like having a manufacturing wizard that gets better with every product it creates.

Real-World Applications

Now, let’s take a stroll through the real-world applications of Industry 4.0 in industrial manufacturing.

Predictive Maintenance

In the past, machines waited to break down before getting attention. Not anymore. With Industry 4.0, machines predict when they might need a little TLC. It’s like a car telling you it needs an oil change before the engine sputters.

Customization at Scale

Thanks to smart manufacturing, customization is no longer a luxury. Mass production coexists with personalized touches. It’s like having a wardrobe of bespoke suits produced on an assembly line.

Supply Chain Evolution

Industry 4.0 isn’t confined to the factory floor; it extends its reach to the entire supply chain. From raw materials to the finished product, everything is tracked and optimized. It’s like orchestrating a flawless dance of resources from start to finish.

The Impact on Jobs

With all this talk about machines taking charge, what about the human workforce?

Upskilling

Industry 4.0 is not a threat; it’s an opportunity. The workforce of the future needs new skills. It’s like upgrading from a basic bicycle to a high-tech electric one – it requires learning a few new tricks.

Collaboration Between Humans and Machines

Think of it as a dynamic duo – humans bring creativity and problem-solving skills, while machines handle the heavy lifting. It’s like Batman and Robin working together for a common goal.

Challenges and Solutions

No revolution comes without its share of challenges.

Cybersecurity

With great connectivity comes great responsibility. Ensuring the security of all these connected devices is crucial. It’s like having a top-notch security system for your digital fortress.

Cost Considerations

Upgrading to Industry 4.0 comes with a price tag. However, the long-term benefits often outweigh the initial costs. It’s like investing in a high-quality kitchen appliance – a bit pricey at first, but it pays off in the long run.

Practical Application

Let’s imagine a car manufacturing plant embracing Industry 4.0. The assembly line, equipped with smart sensors, detects a potential issue in a car component. Without delay, the system communicates this to the maintenance team, who swiftly addresses the problem before it causes a breakdown. This not only saves time and resources but ensures that every car rolling off the line meets top-notch quality standards.

Real-world Impact

In a real-world scenario, a company implementing Industry 4.0 practices experiences a significant boost in efficiency. Production cycles shorten, leading to quicker delivery times for consumers. Additionally, the predictive maintenance aspect prevents unexpected downtimes, translating to higher customer satisfaction and increased competitiveness in the market.

“Predictive maintenance is like having a crystal ball for machines, foreseeing issues before they disrupt production.”

The Future of Manufacturing

As we conclude our journey into the realm of Industry 4.0, it’s evident that we’re witnessing a revolution that transcends the assembly line. It’s not just about making things; it’s about making things smarter, faster, and better.

In the grand tapestry of industrial manufacturing, Industry 4.0 is the vibrant thread weaving together efficiency, innovation, and endless possibilities. It’s not a distant future; it’s happening now, reshaping how we create and build. So, buckle up for a thrilling ride into the future of manufacturing – the Industry 4.0 way!