In the realm of industrial manufacturing, the term “Power Quality” holds paramount significance. Let’s delve into the intricacies of this essential aspect, unraveling its profound impact on the seamless operations within the manufacturing sector.

“Optimal power quality is the unsung hero of efficient manufacturing, ensuring a steady production rhythm.”

Understanding Power Quality: Unveiling the Basics

Power Quality, in simple terms, refers to the consistency and reliability of electrical power. It’s like having a constant and steady flow of energy, ensuring that the machinery and equipment in a manufacturing unit operate smoothly without any hiccups.

The Backbone of Manufacturing: Why Power Quality Matters

Imagine a scenario where your machines are abruptly shutting down or producing defective products. This could be a result of poor power quality. It’s akin to a computer struggling with a fluctuating internet connection – things just don’t work as they should.

The Ripple Effect: How Power Quality Impacts Operations

- Equipment Reliability: Quality power ensures that your machinery remains reliable, reducing the risk of unexpected breakdowns.

- Product Quality: Fluctuations in power can directly affect the quality of the products being manufactured. Consistent power translates to consistent product quality.

- Operational Efficiency: Smooth operations lead to enhanced efficiency. Power quality plays a crucial role in preventing disruptions that can hinder the production process.

Navigating the Technical Landscape: Components of Power Quality

Now, let’s break down the technical jargon associated with power quality into digestible bits.

Voltage Sags and Surges: The Roller Coaster Ride of Power Supply

In simpler terms, voltage sags are like mini power dips, and surges are sudden increases. Both can disrupt operations, akin to a roller coaster ride for your machinery.

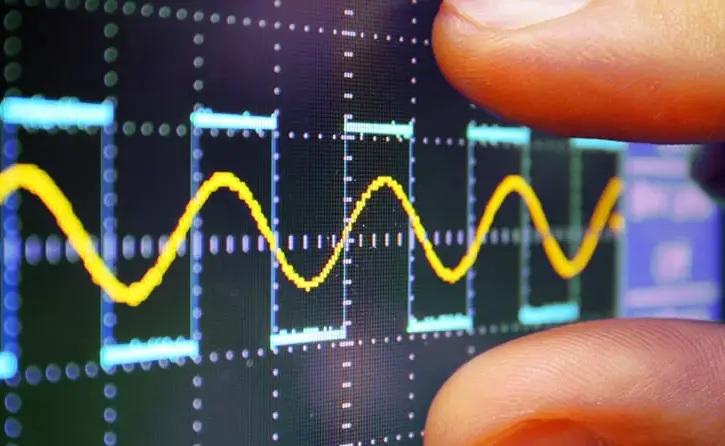

Harmonics: The Unwanted Musical Notes in Power Systems

Harmonics are like the unwanted notes in a musical composition. In power systems, they are additional frequencies that can distort the normal flow of electricity.

Power Factor: Balancing the Equation

Power factor is the efficiency of electrical power usage. Imagine it as using power more effectively, like switching from a conventional light bulb to an LED.

The Impact of Power Quality on Industrial Machinery: A Closer Look

Let’s put on our engineering hats and explore how power quality directly influences the functionality of industrial machinery.

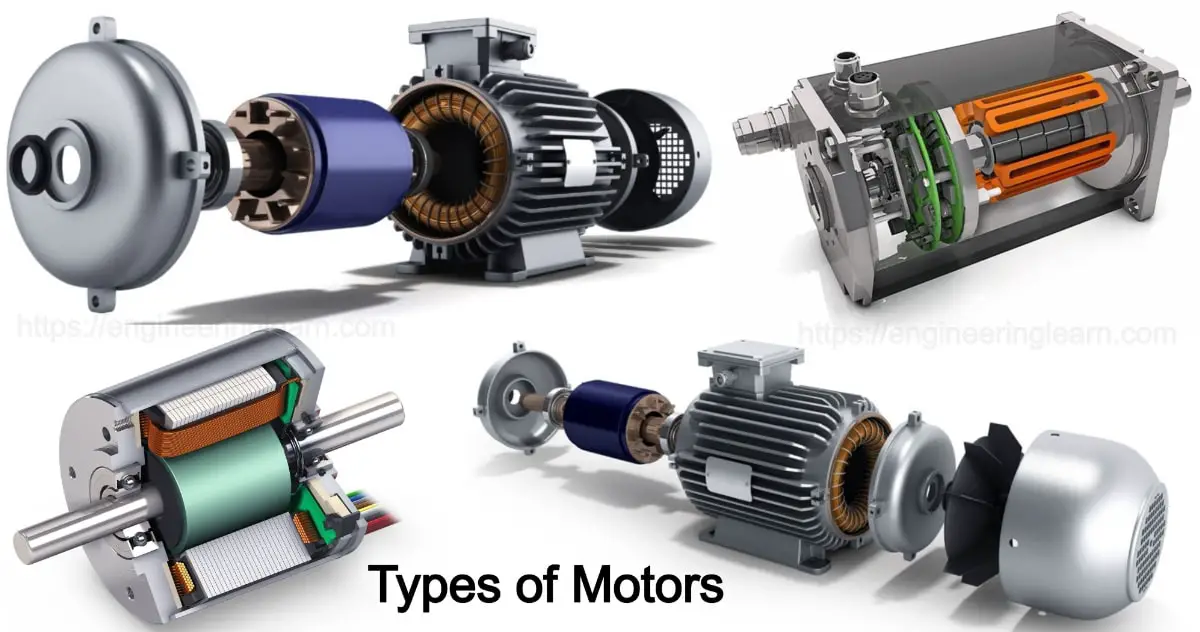

Motor Drives: The Heartbeat of Manufacturing Units

In the manufacturing world, motor drives are the heartbeat. Poor power quality can cause irregular heartbeats, leading to malfunctions and breakdowns.

Sensitive Electronic Equipment: Handling with Care

Modern manufacturing relies heavily on sensitive electronic equipment. Power quality issues can damage these delicate components, akin to exposing them to harsh weather conditions.

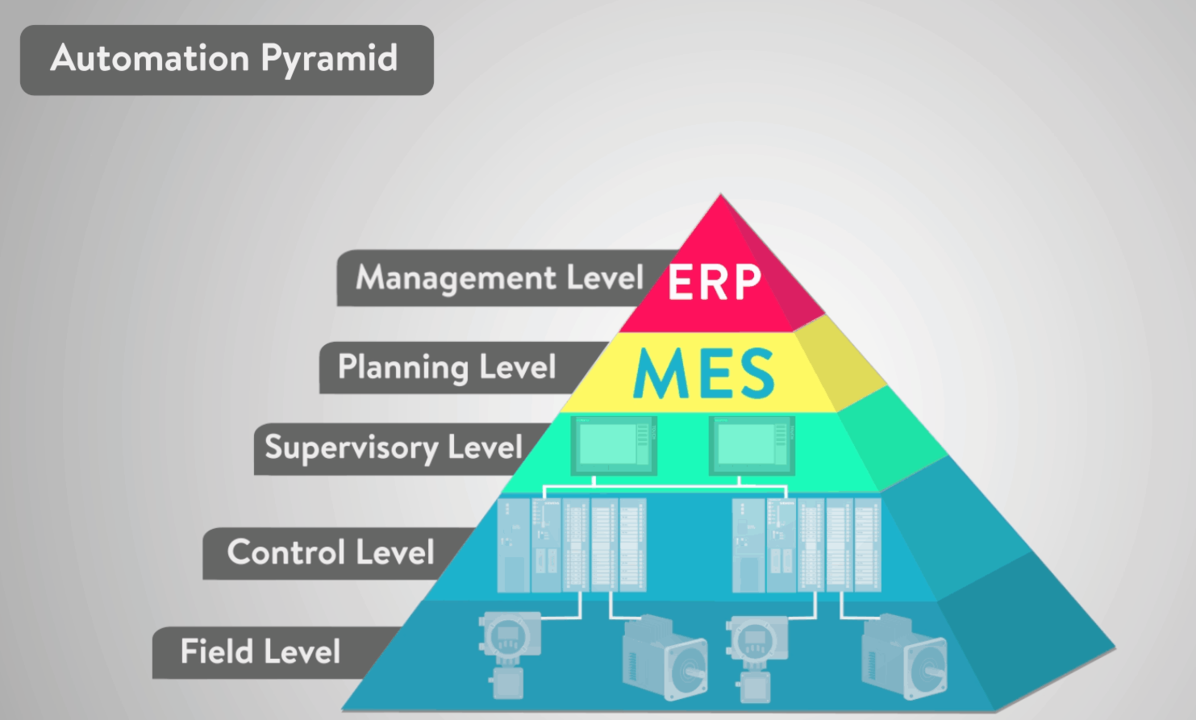

Automation Systems: The Brain Behind the Brawn

Automation is the brain behind the brawn in industrial setups. Fluctuations in power quality can disrupt these systems, causing costly downtimes.

Tackling Power Quality Issues: A Proactive Approach

Now that we understand the potential pitfalls, let’s explore proactive measures to ensure optimal power quality.

Investing in Voltage Regulation: Keeping the Voltage in Check

Voltage regulation is like having a stabilizer for your electrical supply, ensuring it stays within the acceptable range.

Harmonic Filters: Tuning Out the Unwanted Noise

Harmonic filters act like noise-canceling headphones, eliminating the unwanted harmonics from the power supply.

Power Factor Correction: Balancing the Load

Power factor correction is akin to maintaining a balanced load, ensuring efficient use of electrical power.

Practical Application

Imagine a factory using advanced machinery to produce widgets. With optimal power quality measures in place, the machines hum along smoothly, creating high-quality widgets without interruptions. However, if power quality falters, these machines might sputter, causing delays and defective widgets. To prevent this, the factory invests in voltage regulation, like a stabilizer for the electrical supply, ensuring a steady workflow and top-notch widget production.

Real-world Impact

In a real-world scenario, a manufacturing plant experienced frequent power sags. This led to disruptions in their production line, resulting in increased downtime and defective products. By addressing power quality issues through measures like harmonic filters and power factor correction, the plant regained control. Now, with a stable power supply, they not only reduced downtime but also improved product quality, showcasing the tangible impact of power quality on real-world industrial operations.

“In the industrial dance, power quality leads, and machinery follows, creating a symphony of seamless operations.”

Conclusion: A Powerful Finale

In the grand symphony of industrial manufacturing, power quality takes center stage. By understanding its nuances and implementing proactive measures, manufacturers can orchestrate a harmonious production process. As the heartbeat of industrial operations, power quality deserves the spotlight for a seamless and efficient manufacturing journey.