“Valve Automation simplifies complex processes, making industries more efficient.”

In the world of Industrial Manufacturing, where big machines and processes work together to create products we use every day Valve Automation, one crucial player often goes unnoticed – valves. These small but mighty components play a key role in controlling the flow of liquids and gases in various manufacturing processes. Today, we’ll delve into the realm of Valve Automation and explore how it streamlines industrial processes, making them more efficient and reliable.

Understanding Valves in Simple Terms

Valves, in their basic form, are like the taps at home that control the flow of water. In industries, they control the flow of different fluids like oil, gas, and chemicals. Imagine if you could control all those taps at once without running around – that’s where Valve Automation steps in.

How Do Valves Work?

Valves open and close to regulate the flow of liquids or gases. It’s like the switch that turns your lights on or off, but for liquids and gases instead.

What is Valve Automation?

Valve Automation is like having a super-smart robot to control all those valves. Instead of someone turning each valve manually, a system is set up to do it automatically. This makes things faster, more precise, and, most importantly, reduces the chance of errors.

Why Automate Valves?

Automating valves might sound fancy, but it’s like upgrading from a manual car to an automatic one. It simplifies things, reduces the workload, and makes the whole system work smoother.

Benefits of Valve Automation

Let’s take a look at some simple reasons why industries are buzzing about Valve Automation.

1. Precision Control

With Valve Automation, it’s like having a superhero with a laser focus. The system can control the valves with pinpoint accuracy, ensuring the right amount of fluid flows at the right time.

2. Speedy Operations

Imagine a world where things move as fast as you want them to. Valve Automation makes processes quicker, which means products get made faster, and we get to use them sooner.

3. Fewer Mistakes

Humans can make mistakes, but machines following precise instructions? Not so much. Valve Automation reduces the chance of errors, making everything more reliable.

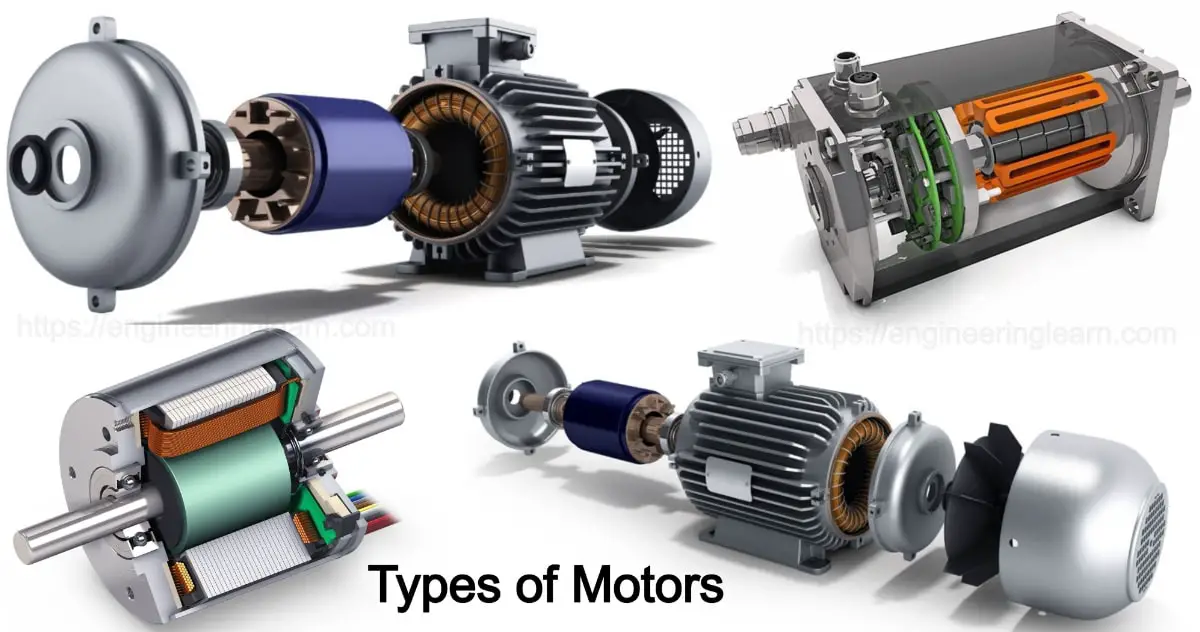

Types of Valve Automation

Now that we know the why, let’s explore the how. There are different types of Valve Automation, each serving a specific purpose.

1. Electric Valve Actuators

Think of these as the muscles of the valve world. They use electricity to open and close valves, making the process smoother and more controlled.

2. Pneumatic Valve Actuators

Air can be powerful too! Pneumatic actuators use air pressure to move valves. It’s like having a little breeze directing the flow of liquids.

3. Hydraulic Valve Actuators

These actuators use the power of liquid to control valves. It’s a bit like how our blood vessels work, ensuring everything flows smoothly.

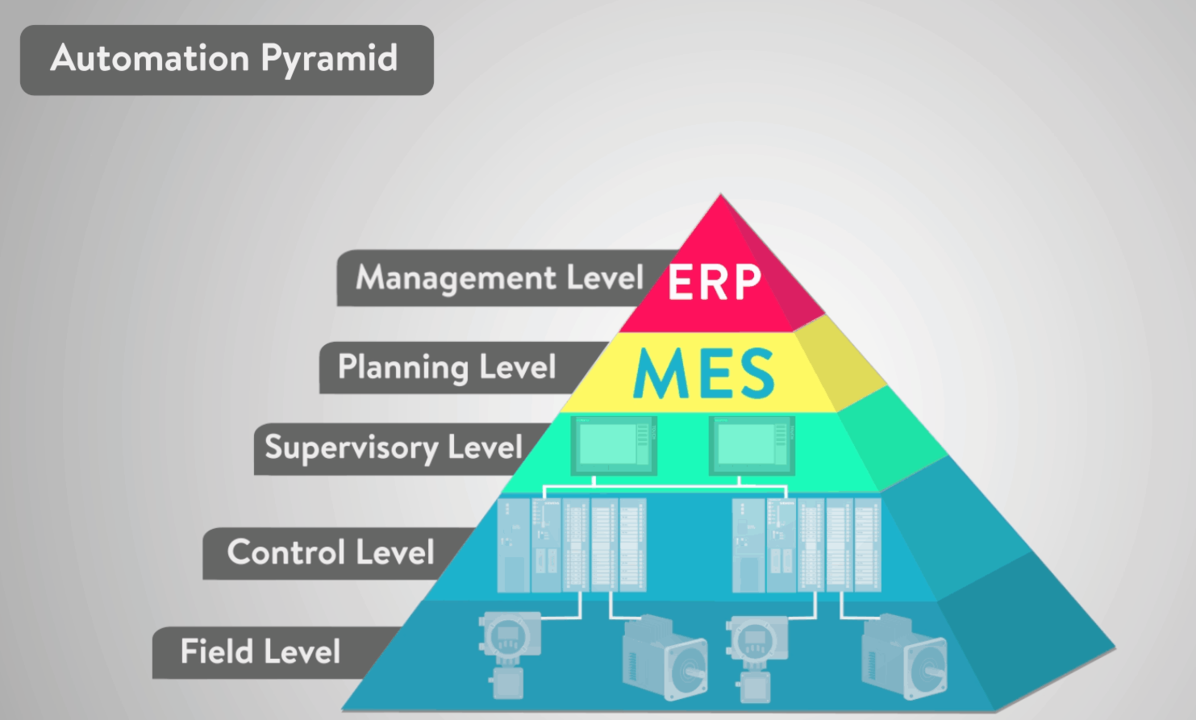

Applications of Valve Automation

Valve Automation isn’t just a cool concept; it’s making a real impact in various industries. Let’s explore some everyday places where Valve Automation plays a vital role.

1. Oil and Gas Industry

In the world of oil and gas, where precision is key, Valve Automation ensures that the right amount of oil or gas is flowing at the right time, preventing wastage and ensuring efficiency.

2. Water Treatment Plants

Ever wondered how clean water reaches our homes? Valve Automation helps in controlling the flow of water in treatment plants, ensuring it’s safe for us to use.

3. Chemical Manufacturing

In chemical plants, where different chemicals are mixed to create products, Valve Automation ensures that the right chemicals are mixed in the right proportions, preventing any mishaps.

Practical Application:

Let’s imagine a car factory using Valve Automation. Instead of workers manually adjusting valves to control the paint flow on cars, a smart system does it automatically. This ensures every car gets the right amount of paint, saving time and preventing errors.

Real-world Impact:

In a real-world scenario, think of a water treatment plant using Valve Automation. It ensures precise control over water purification, guaranteeing clean water for communities. This not only enhances efficiency but also contributes to public health.

Challenges and Solutions

Even superheroes face challenges, and Valve Automation is no exception. Let’s look at some common issues and how they’re tackled.

1. Maintenance Concerns

Like any machinery, valves need maintenance. Regular check-ups and a bit of care ensure they keep working smoothly.

2. Power Failures

What if the power goes out? Well, many systems have backup power sources, like a spare battery in a flashlight. This ensures that even during a power cut, the valves can keep doing their job.

The Future of Valve Automation

As technology advances, so does Valve Automation. The future holds exciting possibilities, with smarter systems and even more efficient processes on the horizon.

1. Artificial Intelligence Integration

Imagine valves that can learn and adapt! Integrating artificial intelligence could make Valve Automation even more intelligent, predicting and preventing issues before they occur.

2. Remote Control

What if you could control valves from the comfort of your office? Remote control features are becoming more common, allowing operators to manage valves from a distance.

In the world of manufacturing, precision is paramount, and Valve Automation is the key.

Conclusion

In the world of Industrial Manufacturing, Valve Automation is like the unsung hero that ensures everything runs smoothly. From controlling the flow of oil in the vast oil fields to making sure the water in our taps is clean, Valve Automation is the invisible force that keeps our world ticking. As technology advances, we can expect even more innovations in this space, making processes more efficient and reliable. So, the next time you turn on a tap or use a product, remember the silent hero working behind the scenes – Valve Automation.