What is Industrial Automation?

In making things, industrial automation might seem hard to understand, but basically, it’s about making stuff work on its own in manufacturing. Picture a bustling factory where machines and computers seamlessly collaborate, diligently crafting products without constant human intervention. That’s the essence of industrial automation — a technological dance that propels industries forward.

“Industrial automation transforms production, making it faster and more reliable.”

Why is Industrial Automation Important?

Making Things Faster

At the heart of industrial automation lies the quest for efficiency. In the world of factories, time is a precious commodity, and industrial automation serves as the accelerator. When we use automation, we make things happen faster in the production process. This acceleration translates to businesses meeting customer demands promptly, a vital aspect in the fast-paced landscape of today’s markets.

Improving Quality

Precision becomes an ally in the pursuit of quality. When we give machines jobs, they do them very precisely. Unlike people, machines don’t get tired or make mistakes, so the quality of the products is always the same and really good. In the world of manufacturing, where precision is paramount, industrial automation emerges as a game-changer.

Saving Money

Efficiency not only impacts time but also finances. Automation, by streamlining operations, can reduce the reliance on human labor for repetitive tasks. While human ingenuity remains irreplaceable, machines handle routine duties, enabling human workers to focus on more intricate and demanding aspects of the production process. This dual collaboration not only enhances productivity but also saves companies valuable resources.

Components of Industrial Automation

Sensors

The unsung heroes of automation are sensors — the eyes and ears of this technological symphony. These sensors detect various parameters such as temperature, pressure, and movement. Think of them as the thermostat in your home, but on a grand industrial scale.

Controllers

If sensors are the eyes and ears, controllers are the brains orchestrating the entire operation. They assimilate information from sensors and make informed decisions, dictating the actions machines should undertake. In essence, controllers act as the supervisors guiding the workforce of machines.

Actuators

Enter the stage, actuators — the muscles of this technological ballet. These components execute the commands emanating from controllers, bringing the automated processes to life. In a way, actuators are akin to the nimble hands that perform the tasks delegated by their digital overseers.

Types of Industrial Automation

Fixed Automation

In the realm of industrial automation, fixed automation is the specialist. It excels in repetitiveness, handling specific tasks with unwavering precision. Picture a production line churning out identical products seamlessly — that’s the domain of fixed automation.

Programmable Automation

Adding a layer of adaptability, programmable automation allows machines to diversify their skill set. It’s akin to having a robotic workforce that can be reprogrammed to handle different tasks based on the needs of the day.

Flexible or Agile Automation

Taking versatility to new heights, flexible automation allows machines to adapt on the fly. It’s like having a robot that can seamlessly switch between tasks without extensive reprogramming. The agility here mirrors the dynamism demanded by modern manufacturing landscapes.

Industrial Automation in Manufacturing

Assembly Lines

Picture a well-orchestrated symphony — that’s what assembly lines are in the world of manufacturing. Industrial automation ensures that products move along these lines efficiently, with each station performing a specific task. The result is a seamless and precise assembly process.

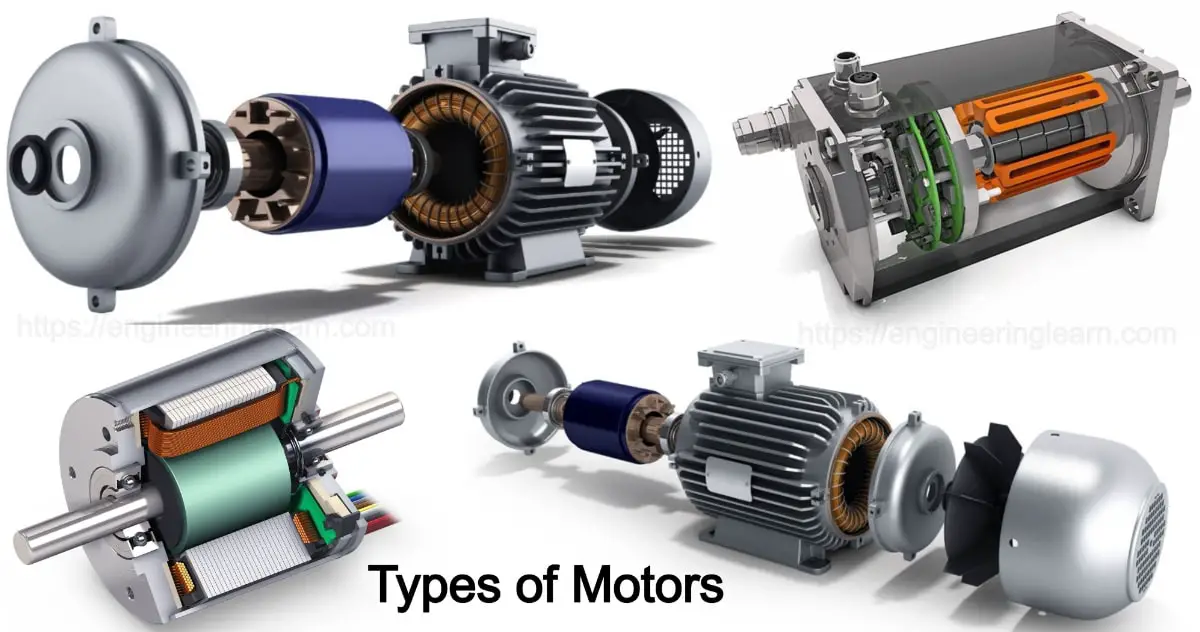

Robotics

Enter the realm of robotics — a cornerstone of industrial automation in manufacturing. Robots tirelessly execute tasks such as welding, painting, assembly, and even packing. Their precision and endurance contribute significantly to the speed and safety of manufacturing processes.

CNC Machines

Meet the artisans of industrial automation — CNC machines (Computer Numerical Control). These machines, guided by digital instructions, shape materials with unparalleled precision. The result is a manufacturing process where each product is a testament to technological craftsmanship.

Benefits of Industrial Automation in Manufacturing

Increased Productivity

The overarching goal of industrial automation in manufacturing is heightened productivity. By expediting production processes, automation allows businesses to meet increasing market demands. This surge in productivity is a key factor in remaining competitive in the global market.

Enhanced Safety

Safety takes center stage in the narrative of industrial automation. Dangerous tasks that pose risks to human workers can be delegated to machines. This transition not only reduces the potential for accidents but also fosters a safer working environment.

Consistent Quality

In the pursuit of excellence, consistency is paramount. Industrial automation ensures that product quality remains unwaveringly consistent. This reliability contributes to building a robust reputation in the market, where quality is synonymous with trust.

Challenges in Industrial Automation

Initial Cost

The road to industrial automation is not without its hurdles, and one significant barrier is the initial cost. Setting up an automated system can be a substantial investment. However, many companies view it as a strategic, long-term investment that pays dividends in increased efficiency and productivity.

Job Displacement

As machines take over repetitive tasks, the concern of job displacement arises. However, it’s crucial to recognize that automation also creates new opportunities. While some jobs may shift, new roles often emerge, demanding more skilled and technical expertise.

Future Trends in Industrial Automation

Internet of Things (IoT)

The next frontier in industrial automation is the Internet of Things (IoT). This interconnected web allows devices and machines to communicate seamlessly. This enhanced communication fosters smarter decision-making and improved coordination within the production process.

Artificial Intelligence (AI)

Stepping into the realm of sci-fi, Artificial Intelligence (AI) is poised to make machines not just smart but intelligent. Machines equipped with AI can learn from experiences, constantly improving efficiency and adaptability. This promises a future where automation becomes increasingly intuitive.

Industrial Automation Practical Application:

Let’s imagine a car manufacturing plant. With robots precisely assemble car parts, making the process faster. This means the factory can produce more cars in less time, meeting customer demands efficiently.

Industrial Automation Real-world Impact:

Consider a mobile phone production line. Ensures each phone is assembled with precision, leading to consistent quality. This not only satisfies customers with reliable products but also boosts the company’s reputation, impacting its competitiveness in the market.

“In the future, the collaboration between humans and machines will redefine innovation in manufacturing.”

Conclusion

In the grand tapestry of manufacturing, industrial automation emerges as the brushstroke that defines modernity. Its impact on efficiency, productivity, and safety is undeniable. As we peer into the future, the trends of IoT and AI hint at a landscape where automation becomes more than a tool — it becomes a partner in innovation. The journey continues, and with each technological stride, industrial automation propels us into a future where the collaboration between humans and machines becomes the cornerstone of progress.