“In the world of manufacturing, robotics like our efficient work buddies, making production smoother and faster.”

In the realm of industrial manufacturing with robotics, where machines and technology converge to streamline processes, advancements in robotics have emerged as a game-changer. These innovations are not just futuristic dreams but tangible realities shaping the landscape of production. Let’s delve into the world of robotics in the simplest terms, exploring how these technological strides are transforming the way we make things.

What Are Robots in Manufacturing?

Robots in manufacturing are like super-smart helpers. Imagine a robot as a special kind of machine that can do tasks on its own, without needing a human to control every move. In industrial settings, these robots are designed to perform repetitive or complex jobs, making production faster and more efficient.

How Do Robots Work?

Robots are like high-tech wizards with sensors and computer brains. They use sensors to “see” and “feel” what’s around them. The computer part of the robot, known as the brain, processes this information lightning fast and decides what action to take. It’s a bit like how your brain tells your hand to pick up a cookie, but way more precise and quick.

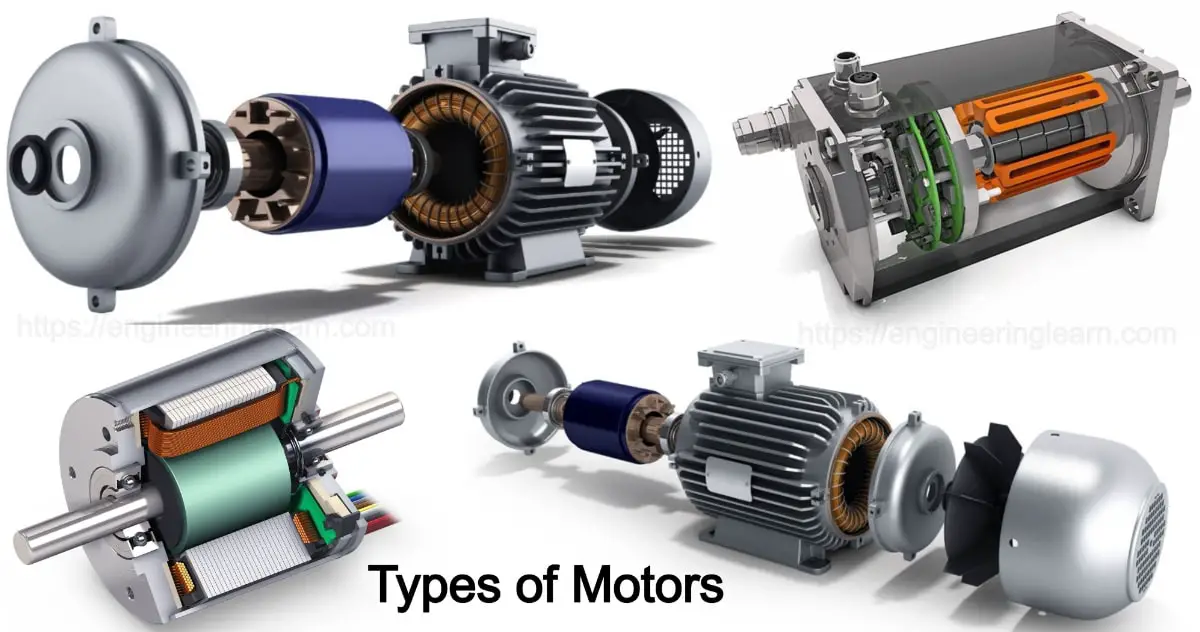

Types of Robots in Manufacturing

- Assembly Line Robots These robots are the superheroes of assembling things. They can put parts together with precision, ensuring everything fits just right. It’s like having a super-accurate puzzle master on the production line.

- Welding Robots Think of these robots as expert welders. They can join pieces of metal together using intense heat, creating strong bonds. It’s like having a master craftsman who never gets tired or needs a break.

- Painting Robots Painting robots are like artists with a perfect paintbrush. They can paint cars, machines, or anything else with flawless precision. Imagine a painter who never messes up or leaves streaks.

- Material Handling Robots These robots are the muscle of the manufacturing world. They can lift heavy things and move them around effortlessly. It’s like having a super-strong friend who’s always ready to lend a hand.

The Impact on Efficiency

Imagine you have a magical helper that never gets tired, never makes mistakes, and works at lightning speed. That’s what robots bring to the table in manufacturing. By taking on repetitive and challenging tasks, they free up human workers to focus on more creative and complex jobs. This not only speeds up production but also makes everything more precise.

Safety First: How Robots Make Factories Safer

Robots are like guardians in the factory, keeping everyone safe. Because they’re super precise and follow instructions to the letter, there’s less chance of accidents. Humans can step back from dangerous tasks, letting robots handle them with ease.

The Future of Robotics in Manufacturing

The future is exciting! Robots are getting even smarter and more adaptable. Soon, we might see robots that can learn from experience, just like you learn from trying new things. This means they can handle new tasks without needing to be reprogrammed every time.

Challenges and Solutions in Robotics

- Cost Challenges Buying and setting up robots can be expensive. But, like buying a super-efficient car, the initial cost pays off in the long run with increased productivity and efficiency.

- Skill Upgradation People need to learn how to work with robots. It’s like learning to dance with a new partner. Training programs help workers understand how to collaborate seamlessly with these technological allies.

- Security Concerns Just like your computer needs protection from viruses, robots need security too. Smart engineers are working on ways to make sure robots can’t be hacked or used for the wrong things.

Practical Application

Imagine a robot in a car factory. It’s like a super-fast worker that puts car parts together without any mistakes. This helps the factory make cars quickly and precisely. The robot follows instructions, making sure each piece fits perfectly. So, the practical application is that the robot speeds up car production, making it efficient and error-free.

Real-world Impact

In a real-world scenario, think about a company using robots for welding. These robots weld metal parts flawlessly, creating strong connections. This not only makes the products durable but also ensures worker safety. With robots handling the tough welding jobs, humans can focus on other important tasks, creating a safer and more productive workplace.

“The collaboration between humans and robots defines the future of manufacturing, bringing forth a new era of precision and innovation.”

In Conclusion

Advancements in robotics are transforming the landscape of industrial manufacturing. These smart machines are not here to replace us but to work alongside us, making production faster, safer, and more precise. As we journey into the future, the collaboration between humans and robots will continue to shape the way we make things, ushering in an era of innovation and efficiency. So, let’s embrace the robotic revolution and look forward to a future where machines and humans work hand in hand for a better and brighter tomorrow.