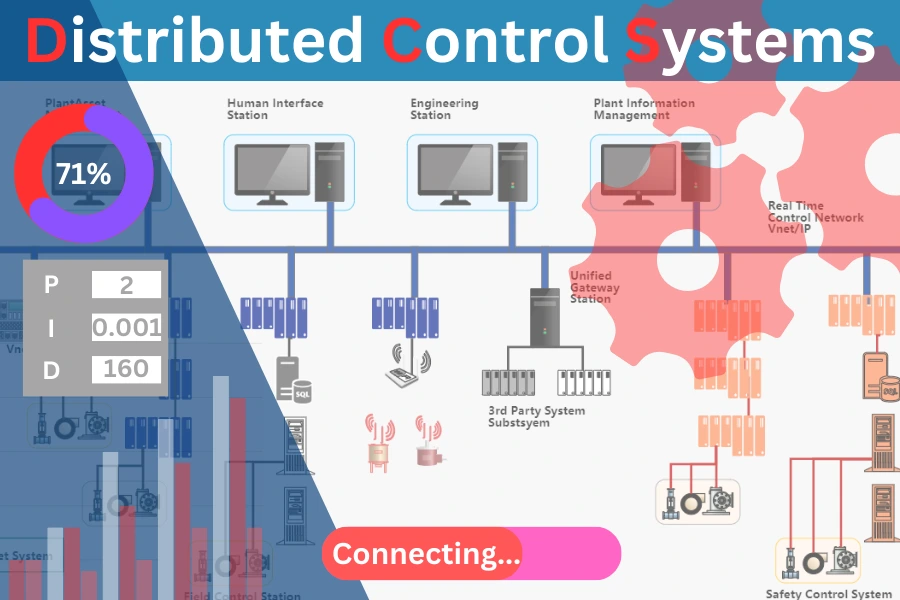

In the vast world of Industrial Manufacturing, the term “DCS” or Distributed Control System holds significant importance. Let’s explore this essential aspect in a simple and comprehensive manner.

“Distributed Control Systems are the unsung heroes of efficient manufacturing.”

Understanding DCS (Distributed Control System)

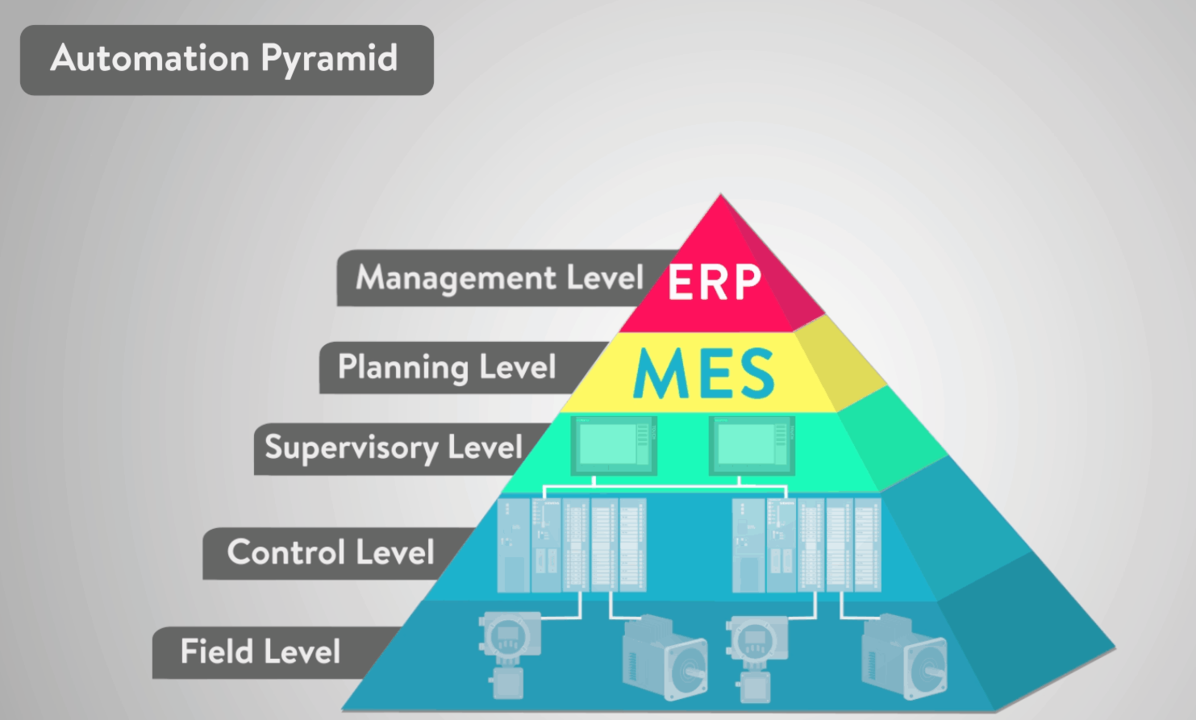

In the heart of Industrial Manufacturing, a Distributed Control System (DCS) plays a crucial role. It’s like the brain that manages and controls various processes within a manufacturing setup. Imagine it as a traffic controller, directing different elements to ensure everything runs smoothly.

The Basics of DCS

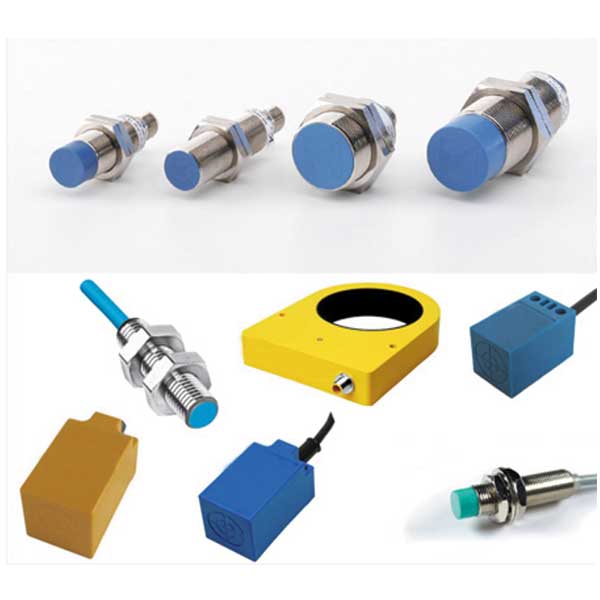

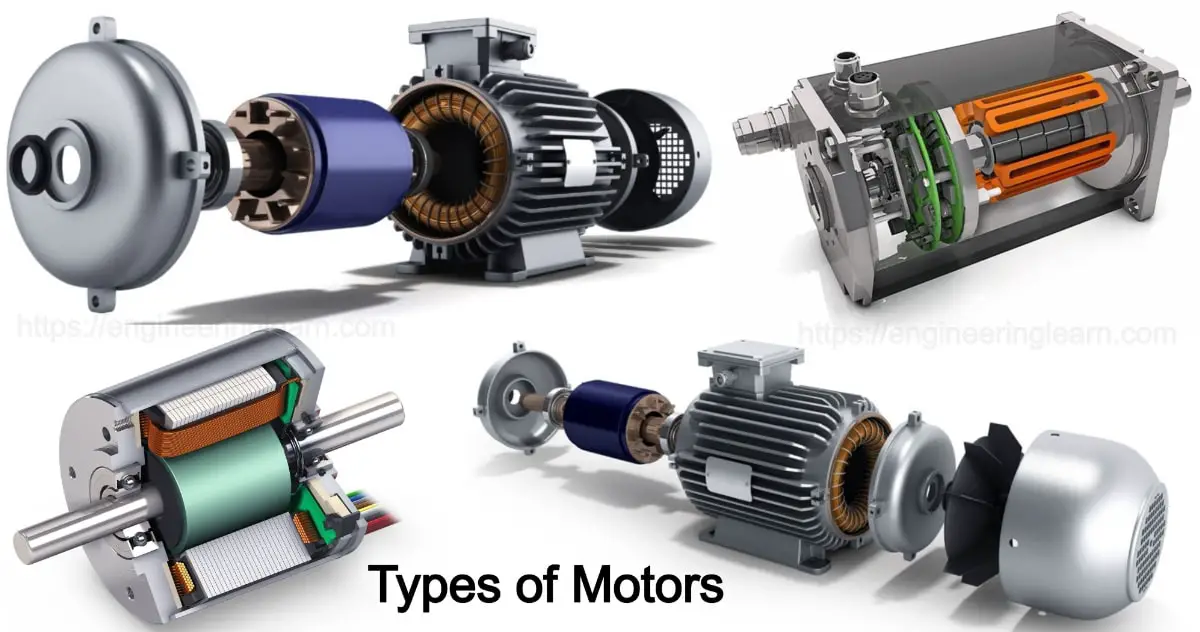

At its core, a DCS is a computerized control system that operates and supervises the multiple components of a manufacturing process. These components can include machinery, sensors, and other devices working together seamlessly.

How DCS Differs from Traditional Control Systems

In the past, factories relied on centralized control systems. DCS brought a revolutionary change by distributing control across various points, enhancing efficiency and flexibility. It’s like having multiple captains steering a ship together, ensuring balance and precision.

Advantages of DCS in Industrial Manufacturing

Now, let’s delve into the benefits that DCS brings to the table.

1. Improved Efficiency

DCS optimizes the manufacturing process, leading to increased productivity. It’s like having a well-orchestrated symphony where each instrument (component) plays its part perfectly.

2. Enhanced Flexibility

Unlike traditional systems, DCS allows for quick adjustments. It’s akin to a chef seamlessly modifying a recipe based on the available ingredients, ensuring adaptability in manufacturing.

3. Real-time Monitoring

DCS provides real-time data, acting as the vigilant eyes overseeing the entire production. Think of it as having a live scoreboard during a sports match, keeping track of every move.

4. Fault Tolerance

In case of a glitch, DCS can isolate and address the issue without affecting the entire production line. It’s comparable to a superhero fixing a small problem before it turns into a catastrophe.

DCS Components in Action

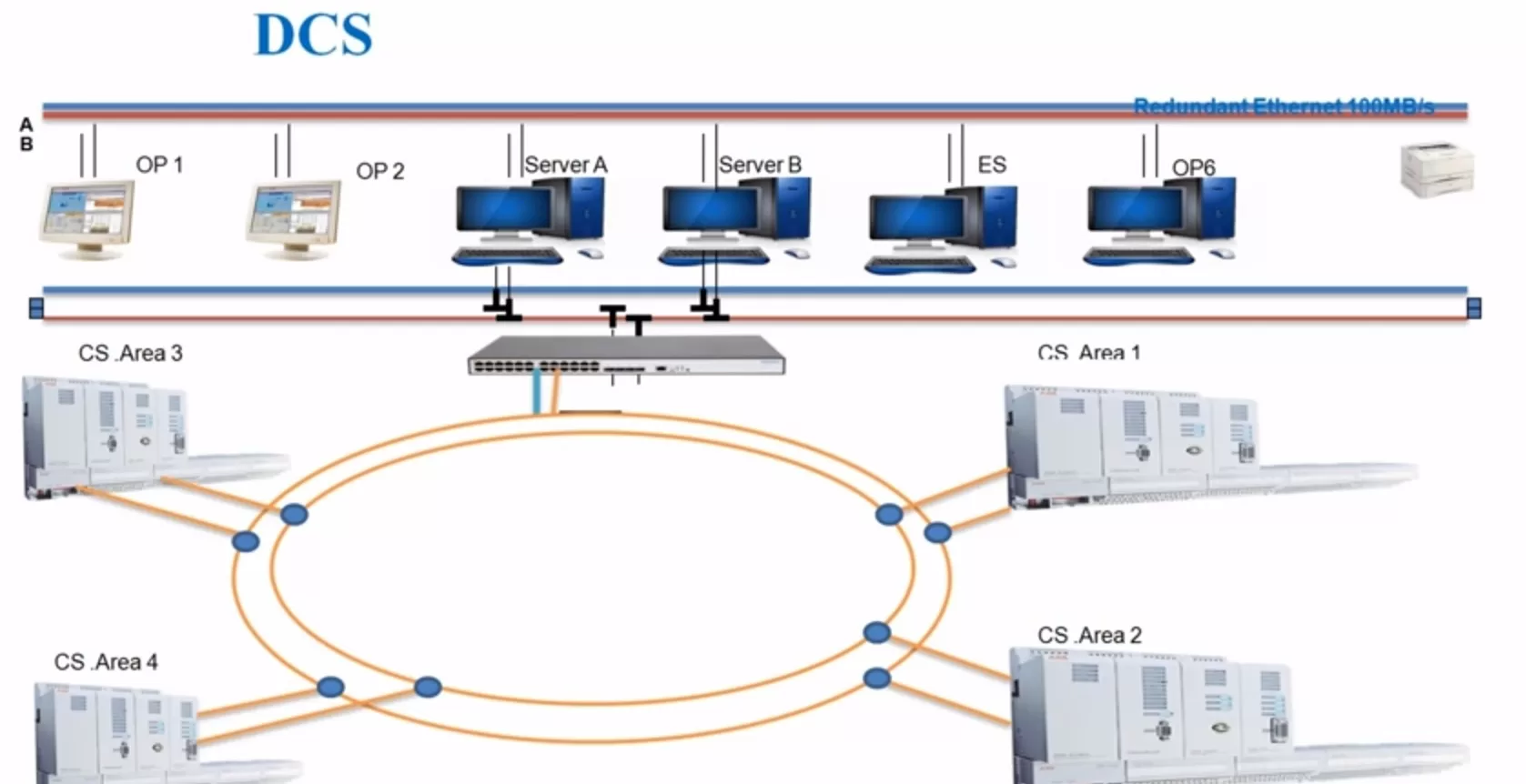

Let’s break down the key components of a Distributed Control System and how they contribute system architecture to the smooth functioning of Industrial Manufacturing.

1. Controllers

Controllers are the decision-makers in the DCS realm. They analyze data and determine the course of action, acting like wise generals leading an army.

2. Input/Output Modules

These modules serve as messengers, transmitting information between the controllers and the various components. Picture them as reliable postal workers ensuring seamless communication.

3. Human-Machine Interface (HMI)

HMI is the face of DCS, providing a user-friendly interface for human interaction. It’s like a user manual that simplifies complex operations for easy understanding.

4. Communication Networks

Just like a well-connected community, communication networks link different components, ensuring they share information effortlessly.

Implementing DCS in Different Industries

Now, let’s explore how DCS finds application in various industrial sectors.

1. Oil and Gas

In the oil and gas industry, DCS manages complex processes, from refining to distribution. It’s like a skilled conductor orchestrating a symphony of activities.

2. Power Generation

DCS plays a vital role in power plants, ensuring efficient electricity production. Think of it as a reliable engine optimizing energy output.

3. Chemical Manufacturing

In chemical plants, DCS oversees intricate reactions, maintaining safety and precision. It’s akin to a meticulous chemist ensuring the perfect blend of ingredients.

Practical Application

Imagine a factory using a DCS to control its production line. The controllers act like managers, making decisions for different machines. If one machine is working slower, the DCS can adjust it, ensuring everything runs smoothly. It’s like having a smart supervisor who keeps an eye on every worker, making sure they work together efficiently.

Real-world Impact

In a real-world scenario, DCS in a manufacturing plant prevents disasters. If a machine malfunctions, the DCS quickly isolates it, avoiding a production shutdown. This is similar to a superhero fixing a small leak before it floods the entire city, saving time and resources.

“In the industrial symphony, DCS ensures every note is played to perfection.”

Conclusion

In the realm of Industrial Manufacturing, a Distributed Control System emerges as a silent yet powerful force, orchestrating operations seamlessly. Its impact on efficiency, flexibility, and real-time monitoring is akin to a skilled conductor leading a harmonious symphony. As we navigate the intricate landscape of Industrial Manufacturing, understanding the significance of DCS becomes paramount for those aiming to grasp the essence of this complex yet essential aspect of modern industry.

Allen Bradley – The Brand of Automation

Allen Bradley is a Very famous brand in the industrial automation area, offering a diverse range of high-quality equipment and software for manufacturing. Allen Bradley Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), Variable Frequency Drives (VFDs), Safety Products, Motion Control Products, Control Components and Industrial Network Products are available in the market. Automotive, oil and…

Industrial Automation and Types

Minimize human interference and optimize product quantity and quality with Automation. Explore fixed, programmable, and flexible types

DCS : Distributed Control Systems

The world of Distributed Control Systems (DCS) in industrial manufacturing. How DCS Increases efficiency and ensures safety. A game-changer for production.

SCADA Systems in Manufacturing

“Explore the world of SCADA systems in industrial manufacturing. These superheroes oversee processes, prevent disasters, and boost efficiency seamlessly.

Industrial Communication Protocols

Industrial Communication Protocols make machines work together, shaping a seamless and efficient production process. The amazing talks as machines and bots.