In the fast-paced world of Industrial Manufacturing, the buzz around Project Automation is hard to miss. But what does it really mean, and why is it crucial for the growth of the industry? Let’s delve into the nitty-gritty of Project Automation, breaking it down into simple terms for everyone to grasp.

“Project Automation is like having a reliable assistant for industrial tasks – it never takes a coffee break.”

Understanding Project Automation

What is Project Automation?

Project Automation is like having a super-smart assistant for industrial tasks. It involves using advanced technology to make machines and processes work automatically, reducing the need for human intervention. Think of it as a high-tech choreographer, orchestrating a complex dance of machines in a factory.

Why is it Important?

In the realm of Industrial Manufacturing, time is money. Project Automation helps speed things up, making production faster and more efficient. This not only saves costs but also ensures that products get to you, the consumer, quicker and in top-notch condition.

The Tech Behind Project Automation

Sensors: The Watchful Eyes

Sensors act like the eyes and ears of Project Automation. They detect changes in the environment and send signals to the machines, telling them what to do. It’s like having a vigilant guard ensuring everything runs smoothly.

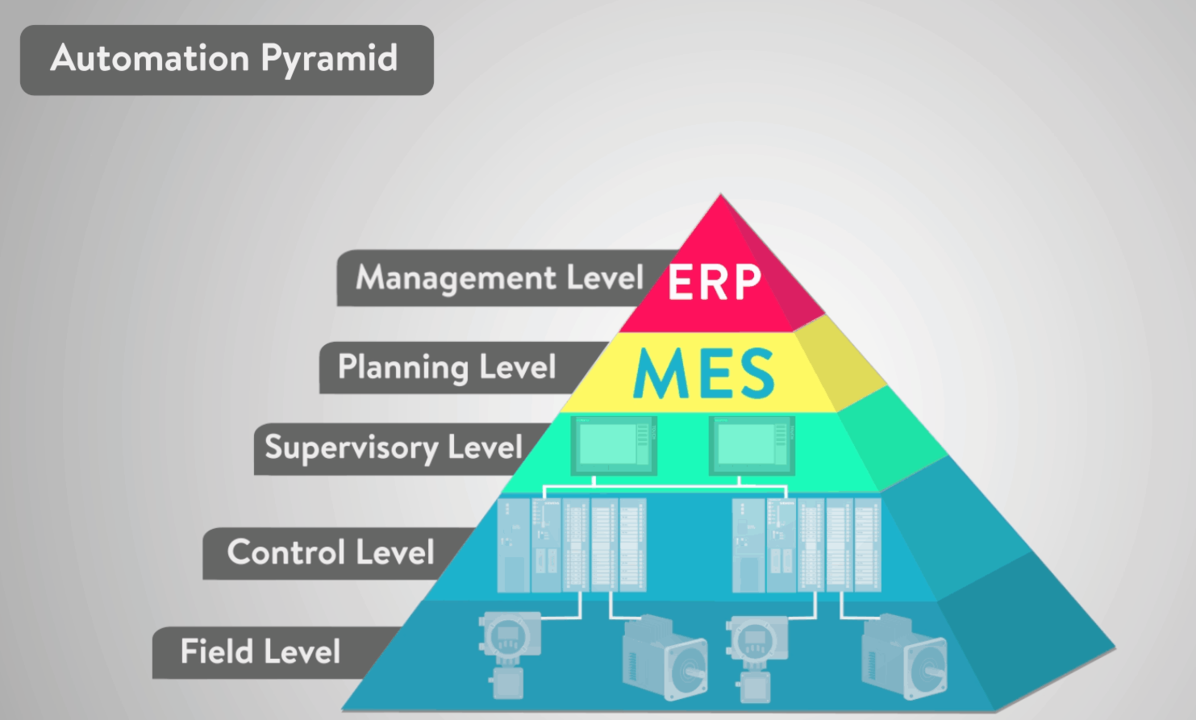

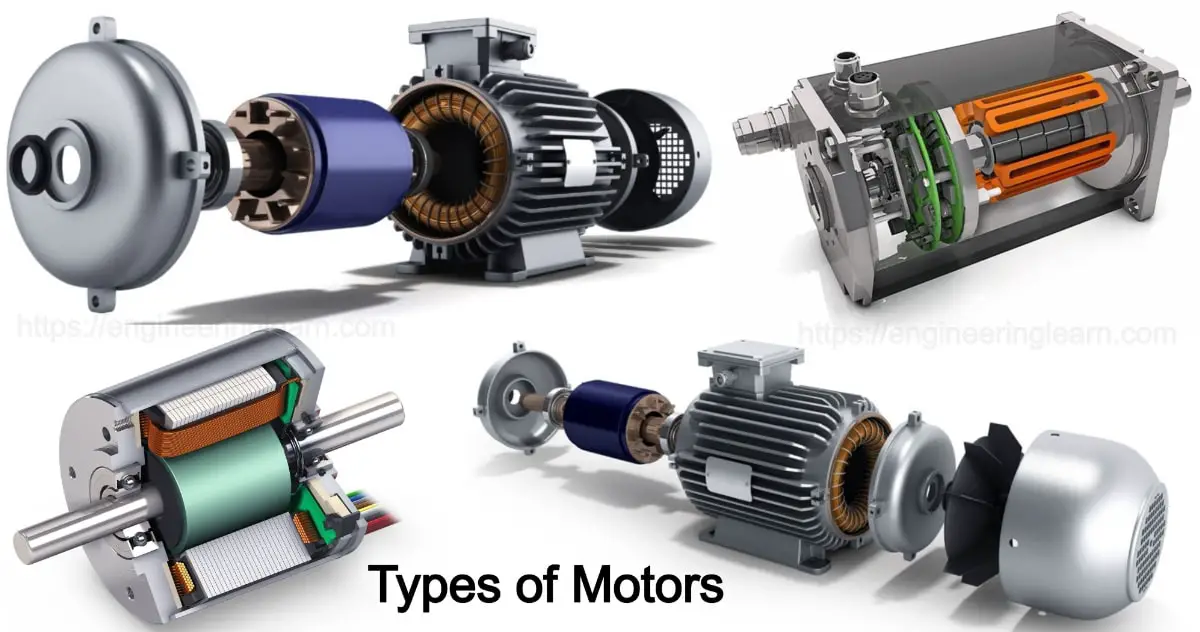

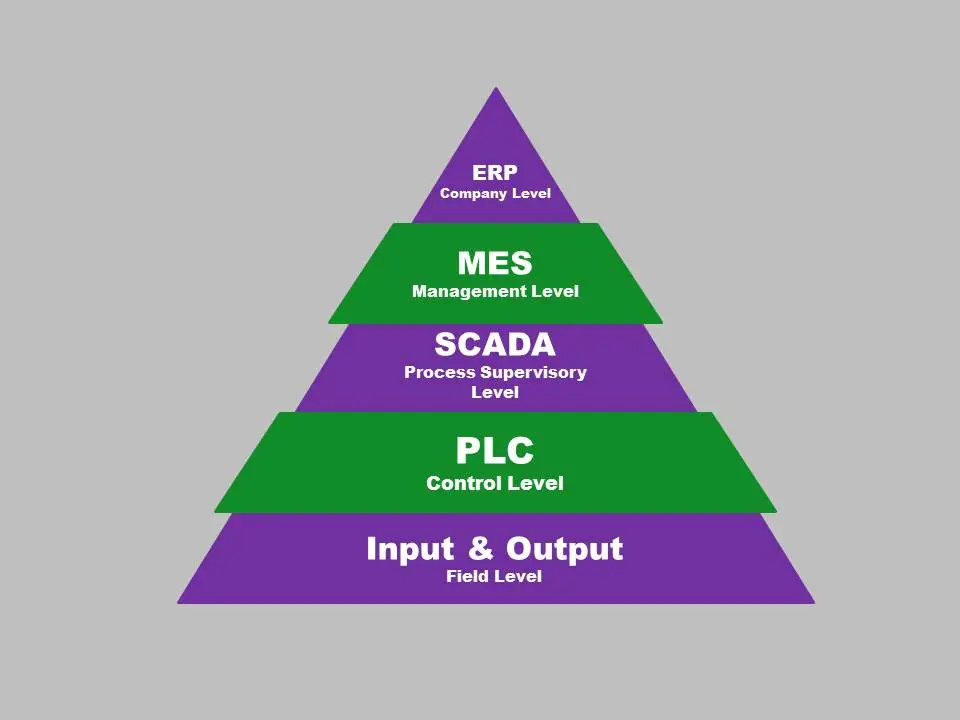

Programmable Logic Controllers (PLCs): The Brains

PLCs are the brains of the operation. They receive information from sensors and decide how the machines should respond. It’s akin to having a wise conductor directing an orchestra, ensuring harmony in the manufacturing process.

Human-Machine Interface (HMI): Your Window into the System

HMI is the interface that lets humans interact with the automated system. It’s the control panel where operators can monitor and manage the manufacturing process. Imagine it as the dashboard of your car, but for a factory.

Benefits of Project Automation in Industrial Manufacturing

Boost in Efficiency

With Project Automation, machines work round the clock without breaks. This means more products can be manufactured in a shorter time, leading to increased productivity.

Reduced Errors

Humans are prone to errors, but machines following automated processes are not. This reduces the chances of mistakes in manufacturing, ensuring consistent quality in every product.

Cost Savings

While setting up Project Automation can be an initial investment, it pays off in the long run. The efficiency gains and reduced need for manual labor result in significant cost savings for manufacturers.

Considerations Before Implementing Project Automation

Assessing Needs

Before diving into Project Automation, it’s crucial to assess what tasks can be automated and how it aligns with the overall goals of the manufacturing process. This evaluation ensures that automation is a strategic move rather than a hasty one.

Training Workforce

Introducing automation means working alongside machines. Training the existing workforce to understand and operate these systems is key to a smooth transition. It’s like learning to ride a bike – a bit challenging at first, but it gets easier with practice.

Cybersecurity Measures

With great technology comes great responsibility. Implementing robust cybersecurity measures is vital to protect automated systems from potential cyber threats. It’s akin to installing a reliable lock on your front door to keep unwanted guests out.

Challenges in Project Automation

Initial Costs

While the long-term benefits are substantial, the initial setup costs of Project Automation can be intimidating for some manufacturers. It’s like buying a top-of-the-line kitchen appliance – the quality pays off, but the upfront cost may make you pause.

Workforce Concerns

Automation can create concerns among the workforce about job security. Addressing these concerns through proper communication and training is essential. It’s like reassuring your team during a period of change – providing support and guidance.

Technological Dependence

Relying heavily on automation makes manufacturers vulnerable to technological glitches. Having contingency plans and regular maintenance checks is like having a backup generator – ensuring things keep running even if there’s a hiccup.

Looking Ahead: The Future of Project Automation in Industrial Manufacturing

As we embrace the era of Industry 4.0, Project Automation is set to become even more integral to Industrial Manufacturing. The ongoing advancements in artificial intelligence and machine learning will further enhance the capabilities of automated systems, making manufacturing processes smarter and more responsive to market demands.

Practical Application

Let’s picture a factory making widgets without Project Automation. Workers are manually operating machines, taking breaks, and sometimes making errors. Now, enter Project Automation. Machines hum along, no breaks, no errors – just smooth production. This means more widgets in less time, cutting costs and boosting efficiency. It’s like upgrading from a bicycle to a high-speed electric scooter – faster, more efficient, and a game-changer for the factory.

Real-world Impact

Imagine a world where every manufacturing plant adopts Project Automation. Products get to consumers faster, prices drop, and businesses thrive. Workers focus on tasks that need a human touch, while machines handle the repetitive work. This isn’t just about factories; it’s about improving lives by ensuring goods are more accessible and affordable. It’s like turning a complicated recipe into a ready-made meal – quicker, simpler, and accessible to everyone.

“In the era of Industry 4.0, embracing automation isn’t just a choice; it’s a necessity for staying competitive in manufacturing.”

In conclusion, Project Automation is not just a trend; it’s a transformative force in Industrial Manufacturing. By understanding its nuances and carefully considering its implementation, manufacturers can unlock new levels of efficiency, quality, and competitiveness. As the industry marches towards a future powered by automation, the key lies in striking a balance between embracing technological advancements and ensuring a human-centric approach. After all, in the dance of automation, humans remain the choreographers, guiding the machines towards a harmonious and prosperous future in Industrial Manufacturing.

Project automation is important for enhancing productivity, reducing cost and ensuring safety. PLCs, SCADA systems, data analysis, AI and ML, cybersecurity and robotics integration are vital considerations. Implementing project automation leads to significant efficiency and productivity improvements, ensuring business success and profitability.