In the bustling world of Industrial Manufacturing, where giant machines and sophisticated technologies converge, the need for safeguarding against the unpredictable strikes of lightning becomes paramount. Let’s delve into the realm of Lightning Arrester and Protection Systems to understand their crucial role in ensuring the safety and integrity of industrial setups.

“In the world of industry, safeguarding against lightning is securing our lifeline.”

Understanding Lightning Strikes

Before we plunge into the specifics of protection systems, let’s grasp the basics. Lightning, a powerful force of nature, can wreak havoc if it finds its way into industrial machinery. Lightning strikes can cause equipment damage, fires, and even endanger the lives of those working in the vicinity.

The Guardian: Lightning Arrester

In the realm of industrial manufacturing, a Lightning Arrester acts as the stalwart guardian against lightning-induced mayhem. Imagine it as a shield, standing vigilant to divert the lightning’s destructive energy away from the delicate machinery within the facility.

How Does It Work?

The Lightning Arrester achieves this feat through a simple yet ingenious mechanism. It provides a low-resistance path for the lightning to follow, directing the powerful electrical surge harmlessly into the ground. In essence, it plays the role of a lightning conductor, safeguarding the equipment from the intense energy levels associated with a lightning strike.

Types of Lightning Arresters

- Rod Type Arrester: This simple and effective design features a rod placed atop the structure, ready to intercept any lightning bolt.

- Mesh Type Arrester: A mesh of conductive material is employed, covering a larger area to capture lightning strikes effectively.

Protection Systems: A Comprehensive Shield

While Lightning Arresters form the first line of defense, a comprehensive Protection System takes the safety game to a higher level. Think of it as an integrated shield, combining various elements to fortify the industrial setup against diverse threats.

Components of Protection Systems

- Surge Protectors: These devices shield against voltage spikes that may occur not only due to lightning but also as a result of internal factors within the electrical system.

- Grounding Systems: Ensuring effective grounding is crucial. Properly grounded systems provide a safe pathway for the dissipation of electrical surges.

- Isolation Devices: These components prevent the spread of electrical disturbances, confining them to specific areas and minimizing the potential for damage.

The Impact on Industrial Processes

Now, let’s consider the tangible impact of Lightning Arresters and Protection Systems on industrial processes.

Downtime Prevention

By preventing damage from lightning strikes, these systems contribute significantly to minimizing downtime in industrial facilities. Unplanned downtime can be a substantial financial burden, making the investment in protection systems a prudent choice.

Equipment Longevity

The wear and tear caused by lightning-induced electrical surges can significantly reduce the lifespan of machinery. Lightning protection measures not only prevent immediate damage but also contribute to the long-term durability of industrial equipment.

Safety Assurance

Beyond the financial aspects, the safety of the workforce is of paramount importance. Lightning protection systems play a pivotal role in creating a secure working environment, reducing the risk of accidents and injuries.

Industry Standards and Compliance

To ensure the efficacy of Lightning Arresters and Protection Systems, adherence to industry standards is crucial. Regulatory bodies set guidelines that help maintain a uniform and high level of protection across different industrial sectors.

Practical Application

Imagine a busy industrial plant relying on complex machinery for production. A Lightning Arrester, like a sturdy shield, safeguards this setup from lightning strikes. Without it, a single lightning bolt could disrupt operations, leading to costly downtime. The practical application is clear: installing Lightning Arresters ensures uninterrupted production, saving both time and money.

Real-world Impact

Consider a factory without Lightning Protection. A sudden lightning strike damages crucial machinery, leading to days of halted production. This not only incurs hefty repair costs but also impacts deadlines, contracts, and customer trust. With Lightning Arresters and Protection Systems in place, this real-world scenario transforms. Operations continue seamlessly, costs are saved, and the business maintains its reliability.

“Lightning protection isn’t just about machines; it’s about ensuring a safe working environment for all.”

Conclusion: A Shield Against the Unseen

In the realm of Industrial Manufacturing, where every second counts and precision is the key, protecting against the unseen threat of lightning is non-negotiable. Lightning Arresters and Protection Systems stand as silent guardians, ensuring the continuity of operations and the safety of all involved. As we navigate the complex world of industrial technologies, let’s not underestimate the power of these unassuming yet indispensable components that shield us from the forces of nature.

Standard for the Installation of Lightning Protection Systems

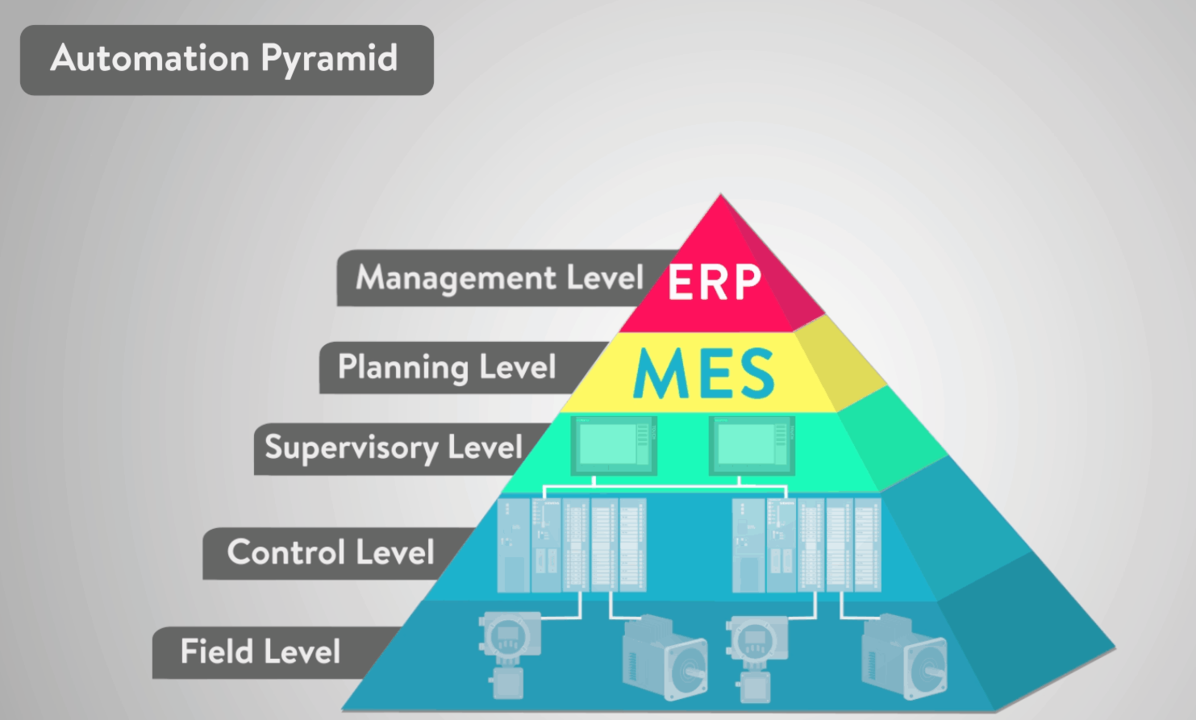

- Upgrading and Retrofit Industrial Machines

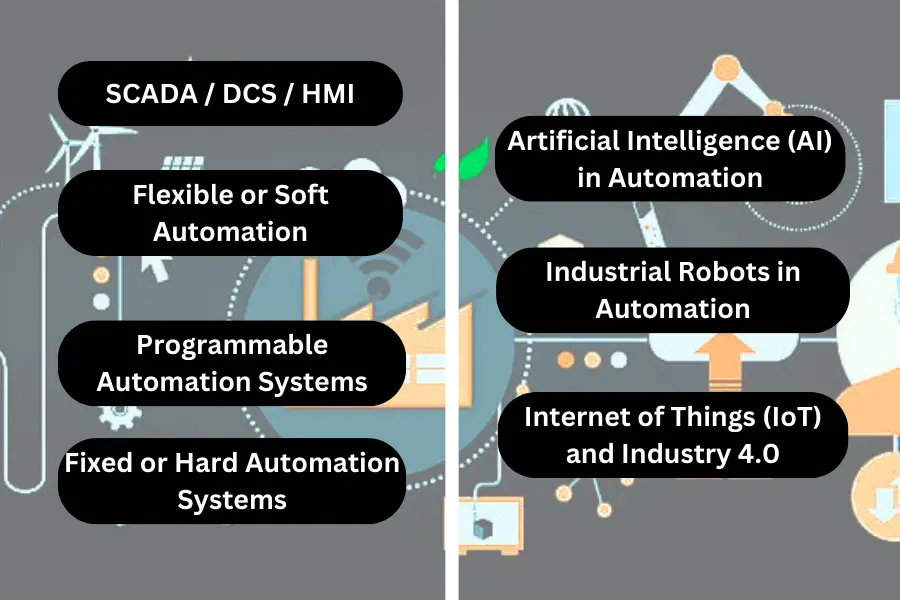

- Types of Automation Systems

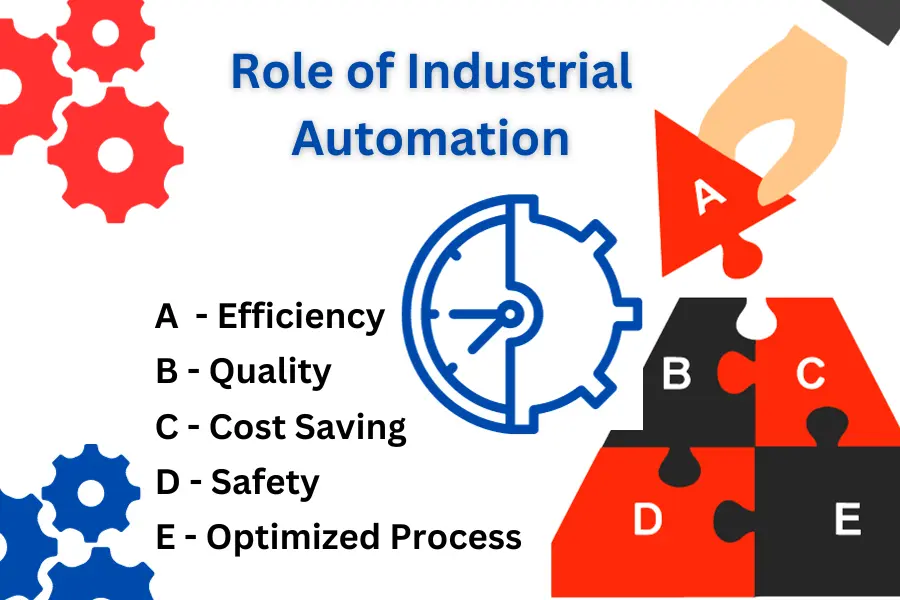

- The Role of Industrial Automation

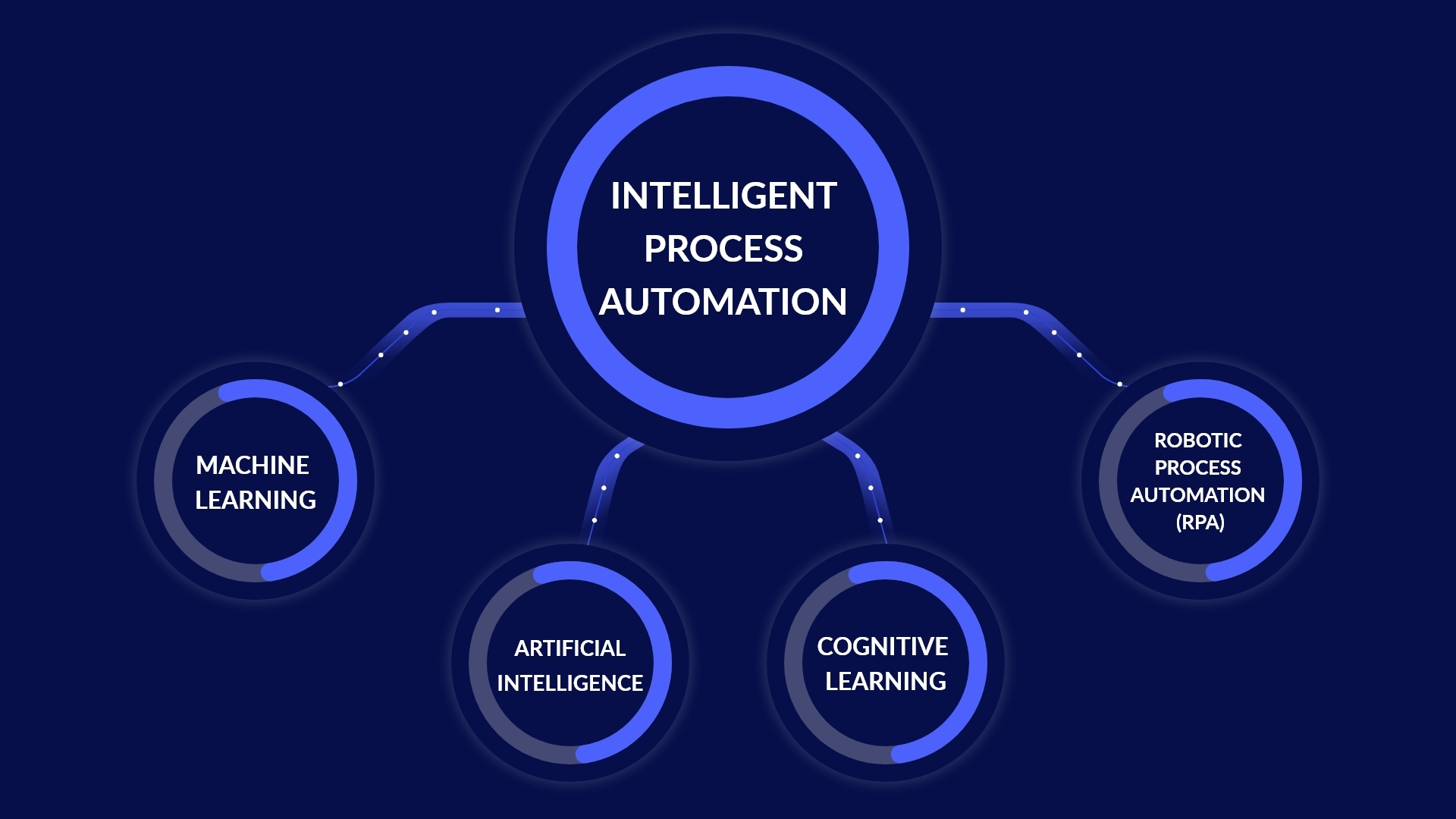

- The Future of Machine Automation

- Switchgear for Power Controls

- Switches: Types and Uses

- Streamlining Processes with Valve Automation

- Streamline Process with Automation